Technologies

Over decades in the industry, PetroTrace employees have mastered, developed, tested and improved dozens of technological solutions that allow us to solve the most complex problems more accurately, better and/or faster across the full range of our operations from seismic data processing to uncertainty evaluation in reservoir forecasts. Some of these technologies are now widespread and some are our "know how," making PetroTrace's service offering unique.

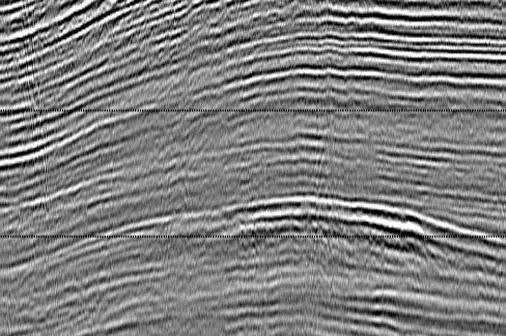

Construction of complex seismic images

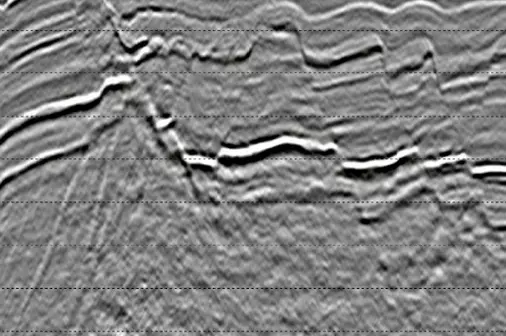

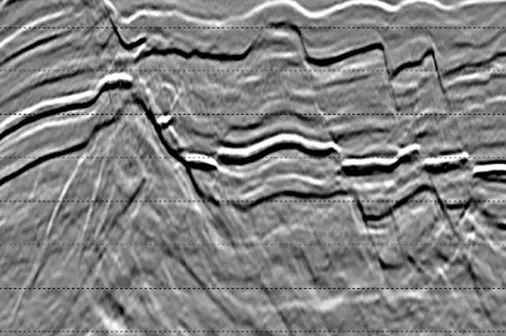

Previous Processing (PSDM).

PetroTrace processing (ES360).

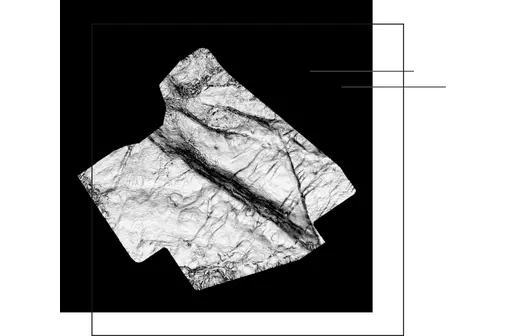

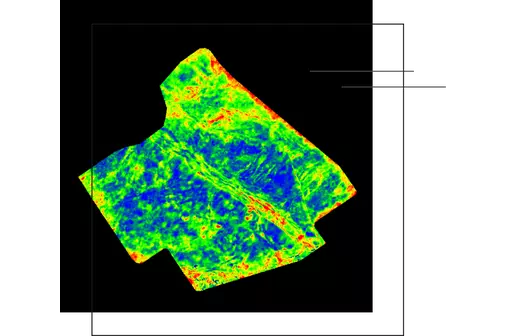

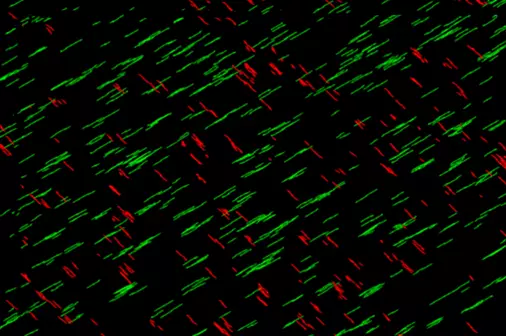

Diffraction imaging

The "Coherence" attribute map.

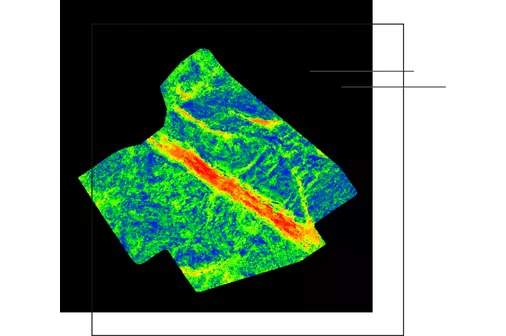

“Anisotropy” attribute map.

"Diffraction component" attribute map.

Processing and interpretation of seismic data for engineering proposes

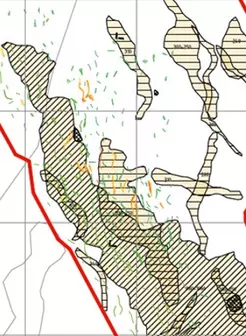

Map of geoengineering risks

Integrated uncertainty modeling

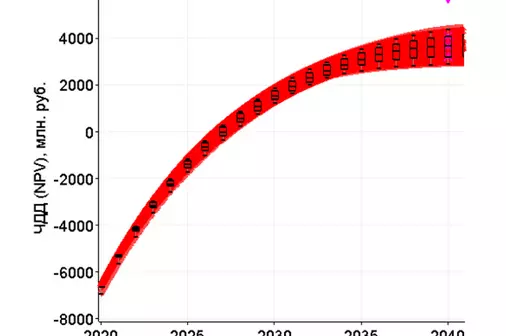

Multivariate project NPV forecast.

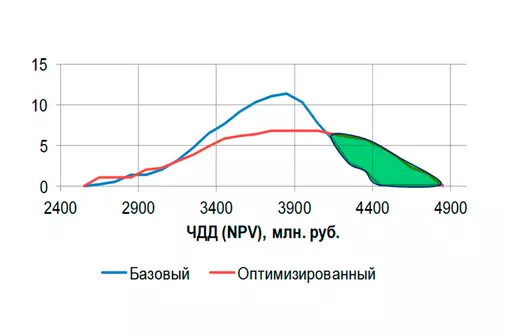

NPV probability distribution of the project before and after optimization.

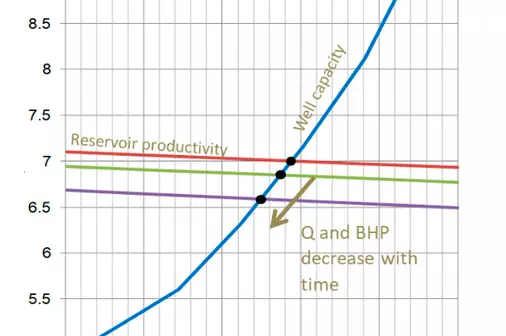

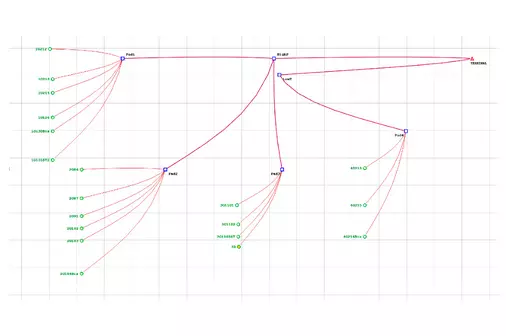

Integrated modeling

Dependence of well flow rate on bottomhole pressure and change in the "operating point" of the well as the field depletes in the integrated model.

Gathering system for one of the gas condensate fields, used as part of the integrated model.

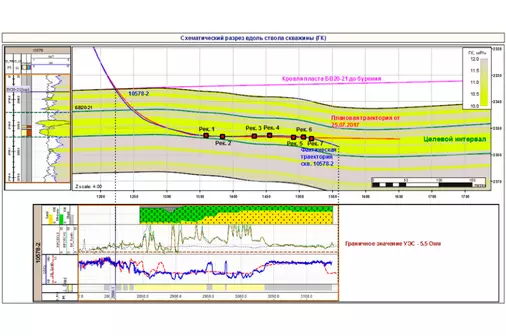

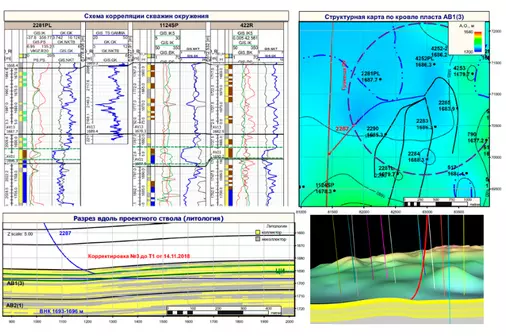

Geological support for drilling opertaions

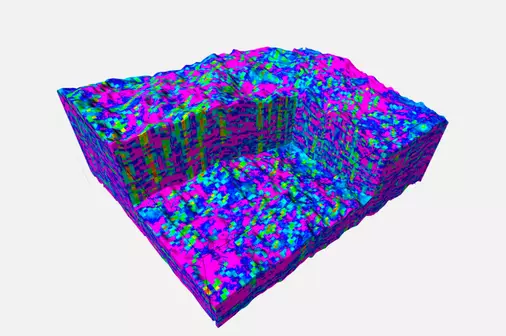

Forecasting and modeling of fractured reservoirs

Realization of a discrete fracture model based on interpretation of the intensity of diffraction energy.

Three-dimensional grid model of the spatial distribution of effective permeability (fractures plus matrix) along one of the directions.

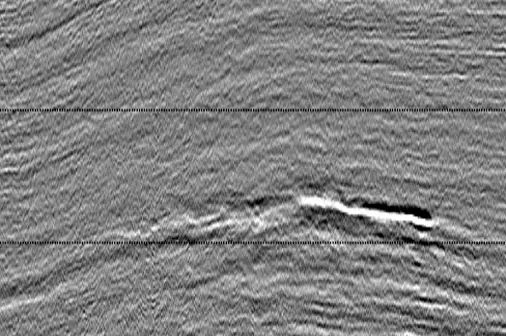

DI Monitoring (4D)

Example of a 4D response at the start of processing.

Example of a 4D response in the final processing.